- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Dairy & Cheese

Dorner has a line of conveyors designed to meet the strict requirements of USDA Dairy regulations and 3-A Sanitary Standards. We have experience handling a variety of dairy products such as: cheese slices, cheese blocks, mozzarella balls, bulk cheese shreds, brine tank extractions and more. With our range of expertise, Dorner can custom design a system to meet your unique need.

At Dorner, food safety is paramount. The hygienic design of our conveyors allows for effective sanitation with conveyors that are quick and easy to clean.

Benefits of Dorner’s Sanitary Conveyors

- Dorner’s Ultimate line of conveyors are designed to meet 3-A Sanitary Standards and USDA Dairy regulations.

- By eliminating horizontal surfaces, blind spots and harbor points, food and water won’t accumulate, preventing the growth of bacteria.

- Easy access to all areas of the conveyor for cleaning allows you to keep lines running and the conveyor at the highest level of sanitation.

- Eliminating the chances of bacteria and contamination creates a safer conveyor and prevents the spread of illness to your customers.

Clean-in-Place Design

- Less downtime

- Sanitary wash down design

- Improved cleaning efficiency

AquaPruf® Series Conveyor

Using an AquaPruf series conveyor from Dorner is a great way to move product along while maintaining sanitary requirements. The AquaPruf series is designed with food sanitation requirements in mind. These design features include:

- Tip-up, tool-less pulleys and belt lifters for easy access for cleaning

- Rounded cross members to eliminate horizontal edges

- Solid UHMW wear strips for quick drainage and easy cleaning

- V-guided belt tracking

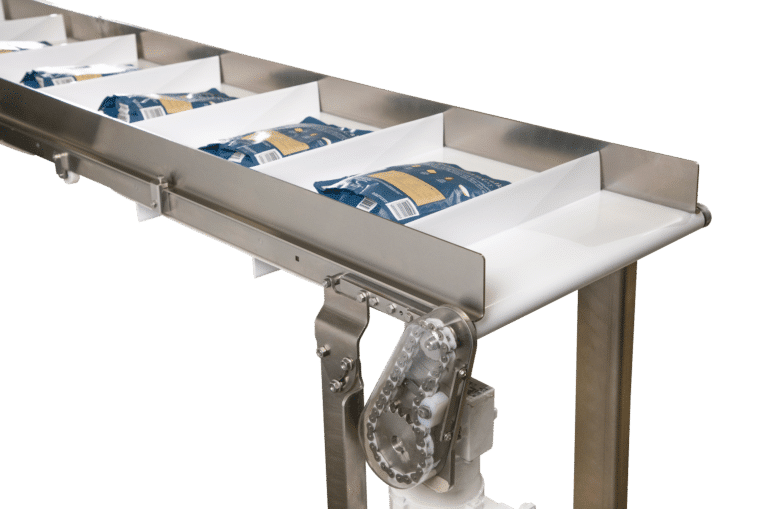

AquaGard® Series Conveyors

The AquaGard line of conveyors is designed for a wide variety of applications in sanitary environments that require conveyor wipe-downs. Features include:

- Solid UHMW wear strips located in welded cross members for durable belt support

- Frame constructed of TIG welded 304 stainless steel

- Open design with minimal horizontal surfaces

- Low-profile frame and flexible belt options

Engineered Solutions

Dairy & Cheese Automation

AquaGard LP

- Quick five-minute belt change for increased uptime

- Compact and enclosed tensioning system providing smooth and snag-free cleaning

- 304 stainless steel frame, head and tail plates

- V-Groove frame with guided belt ensures accurate tracking

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Streamlined design fits where other conveyors do not

- A variety of FDA-approved belting to meet application needs

- BISCC Certified for baked goods and confectionery

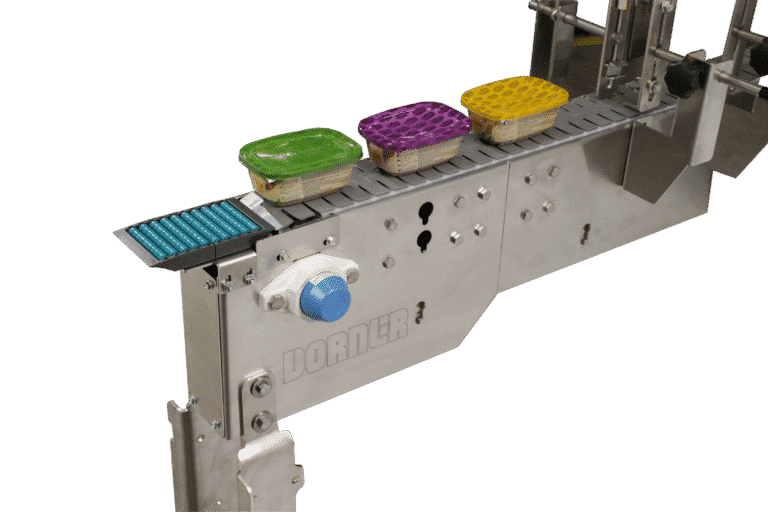

AquaGard GT

- Easy integration with machinery and other produciton equipment

- Fully adjustable incline/decline knuckle modules up to ± 30°

- Welded 7ga stainless-steel stands and open frame design for easy cleaning

- Standard angle adjustment stands with leveling adjustment of ± 51 mm (2″)

- Single or double roll stainless steel-backed guiding with tool or tool-less adjustment options

- Long Conveyor Runs & Fast Belt Speeds

- Pinch Free & Finger Safe Design

- Modular design for greater flexibility

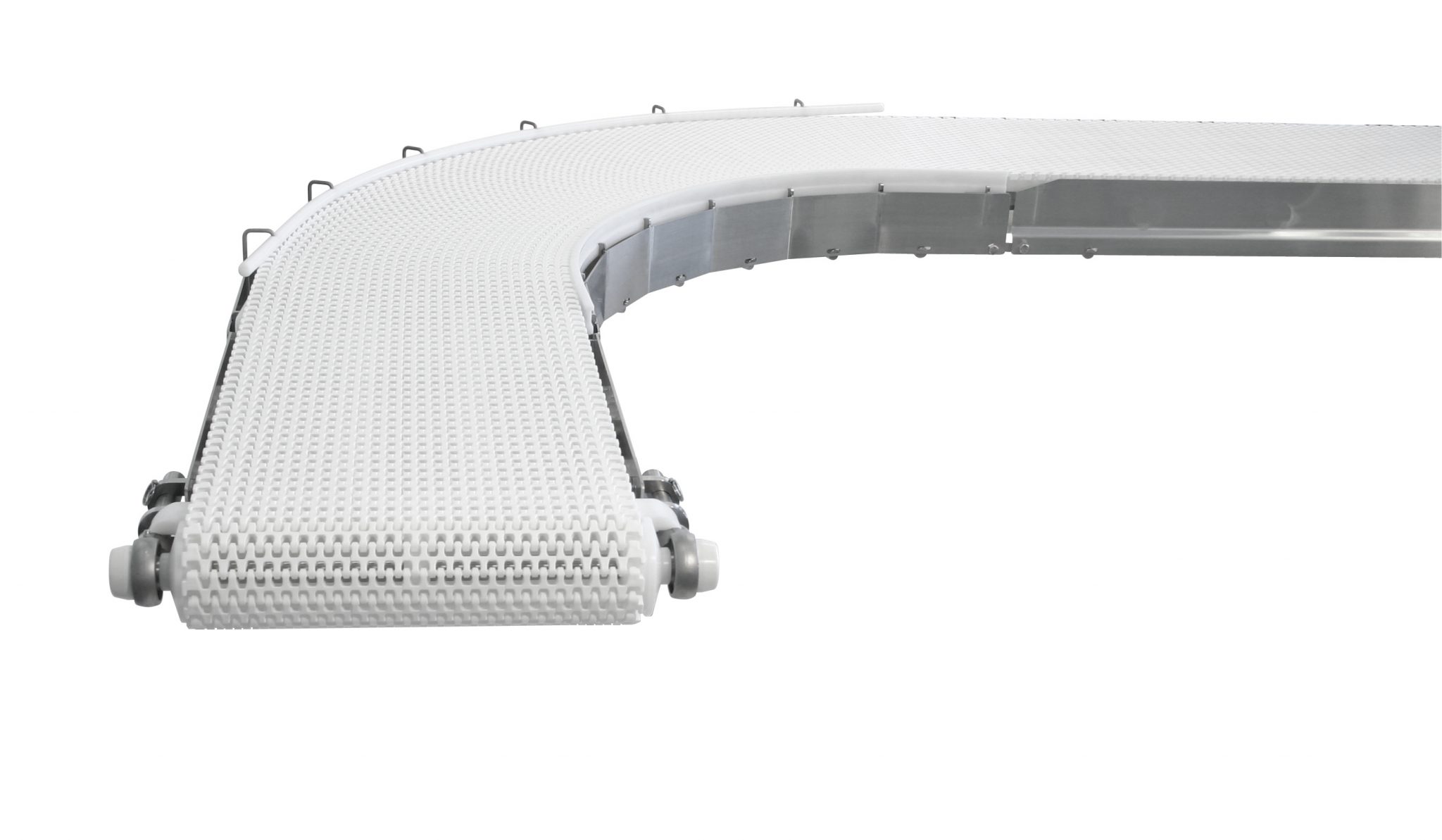

AquaGard 7350 Conveyors

- Rugged and Durable Design

- 304 Stainless Steel frame features open design with minimal horizontal surfaces

- Designed for wipe down and low pressure wash-down with non-caustic chemicals

- V-guided belt tracking on belted models

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Safest chain in the industry with chain openings less than 4 mm even on curves

- Unique chain design virtually eliminates friction providing capacity for up to 4 curves on a single conveyor

AquaPruf Conveyors

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

AquaPruf Ultimate Conveyors

- All surfaces on internal frame components are polished to 32 microinch, except belted product.

- All bearings are external to the conveyor and a minimum of 25 mm away from the food zone.

- Drive sprocket design includes a quick cleaning system to ensure cleaning can be done below the sprocket surface.

- Patent pending idler tail cleaning system on Modular Belt and Positive Drive Belt models.

- Belting / Chain offered meet strict 3-A, USDA and NSF requirements.

- All support stands use only sanitary threadless feet designs.

- Radii on all internal components meet the 6 mm (0.25″) standard requirement.

- Conveyor cleaning guideline is provided specifically for effective cleaning of the Dorner product.

AquaPruf VBT

- Continuous TIG Welded 304 stainless steel frame

- #4 Polish on all surfaces

- Open frame and tool-less design for ease of cleaning

- Drive Gearmotor located on main column outside food drop zone

- Staggered Sidewall Belt provides 15% more pocket capacity than traditional sidewall belt

- Self-Releasing Sidewall improves product release

- Staggered Sidewall can be individually and easily repaired if damaged

- Clean-through Side Wall Design improves clean-ability and reduces cleaning time and water usage

- Quick Belt Change

- Quick Change open-frame design allows belt change in approximately 20 minutes

- Tool-less removal of idlers and belt supports

- Loose belt drops down main column

- No belt tensioning needed

Sanitary Roller Conveyors

- Frame is constructed of continuous TIG welded 304 stainless steel for durability in tough applications

- Integral 1” high side for product containment or low side for maximum flexibility

- Solid Acetal rollers and guides simply lift out of UHMW guide for quick for access to frame during cleaning

- Hollow Tube spring loaded roller can be removed quickly for access to frame during cleaning

- Optional welded end stop available for durability

Dorner — Asia

Dorner (M) SDN. BHD.

128 Jalan Permatang Damar Laut, Bayan Lepas 11960

Penang, Malaysia

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy